It is specially designed to meet the needs of small and medium-sized restaurants, hospitals, hotels, dining halls, schools, dormitories, restaurants and other industrial kitchens to process materials such as meat and vegetables.

The Zirk machine is suitable for health with its stainless body and blade. It appeals to industrial kitchens of different sizes with its model that has a maximum processing capacity of 5 kg of meat and 10 kg of vegetables.

- The Zirk machine is used to quickly and homogeneously chop materials such as boneless meat and vegetables.

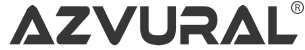

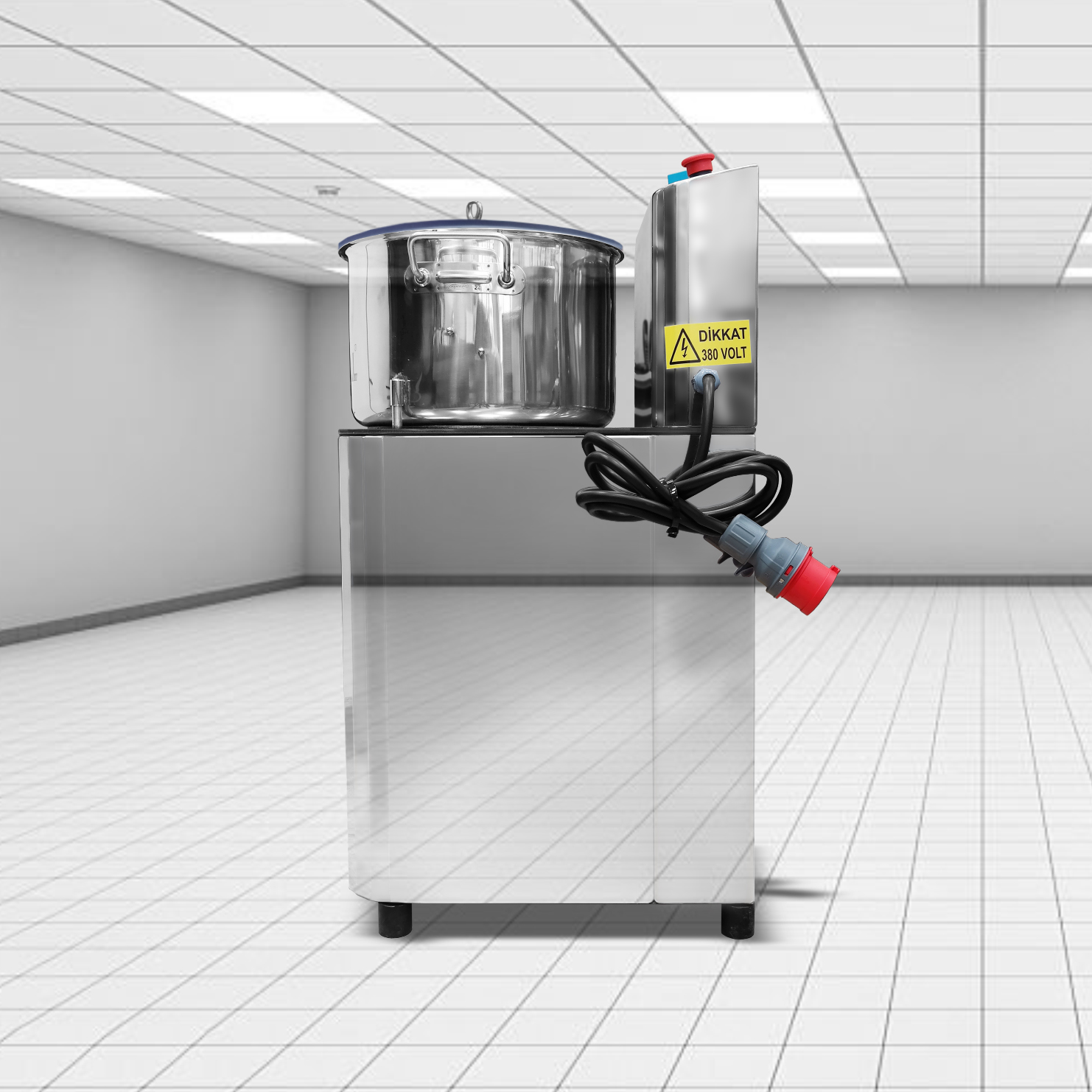

- The zirk machine and its boiler have a stainless body with 304 quality chrome mirror features of German origin.

- The boiler has a transparent, plexiglass lid with a magnetic relay locking mechanism. It has a maximum capacity of 5 kg meat / 10 kg vegetables.

- There are 2 stainless steel knives in the pot.

- The control of the Azvural Zirk machine is done via the panel located on the upper back section.